GEDALU system

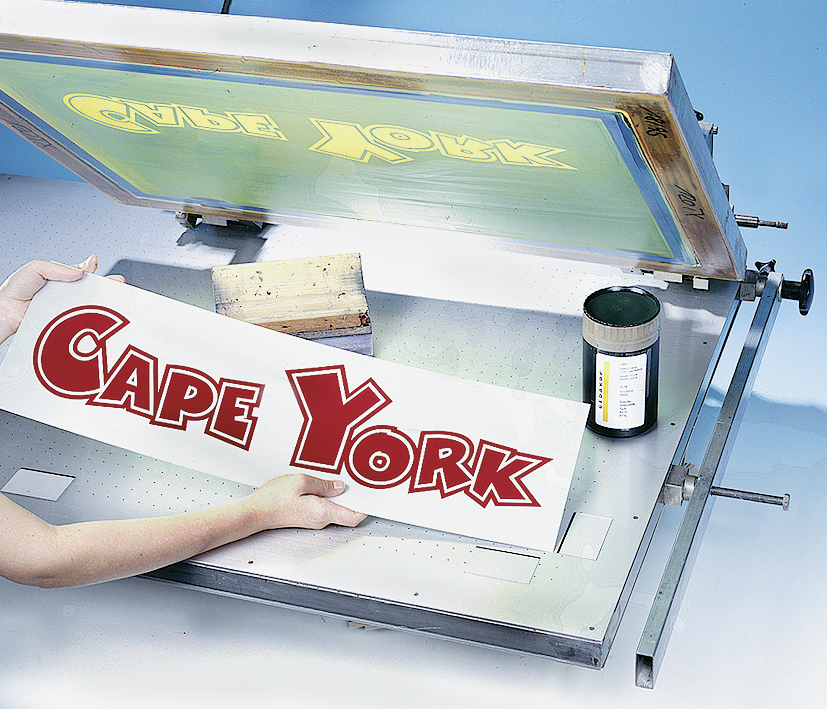

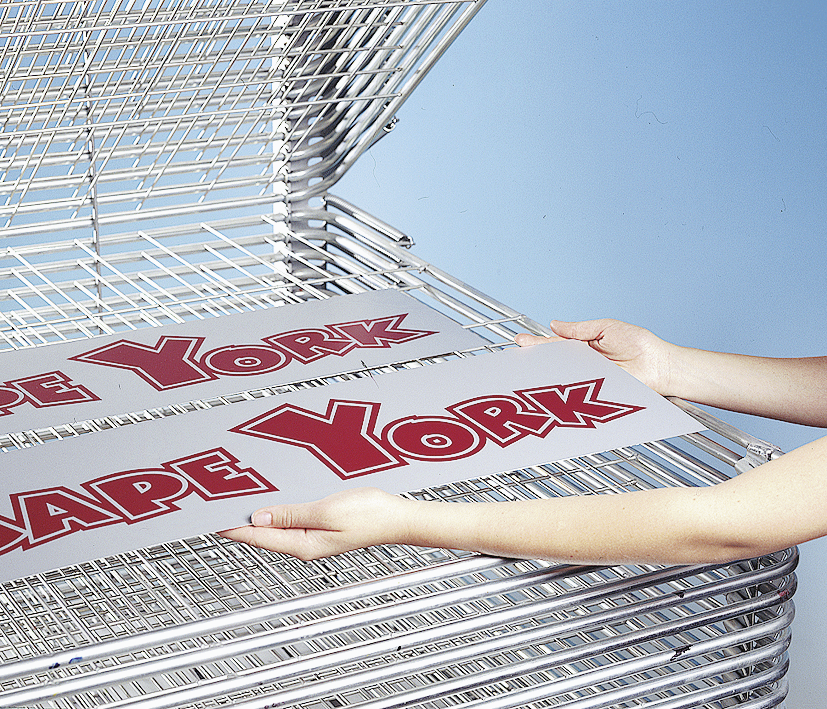

Screen printing production of multicolored aluminum anodized signs in series production (aluminum anodized vacuum).

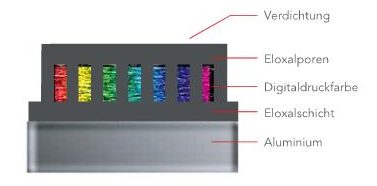

Why open-pored GEADALU panels?

Because the anodized pores are protected with a liquid protective layer (no loss of material due to closed pores). Plates can be touched without gloves (protective layer prevents fingerprints and thus material waste). Thanks to the special drying process during production, there are no rinse stains on the surface (no loss of material due to cloud formation during printing).

Deutsch

Deutsch Français

Français