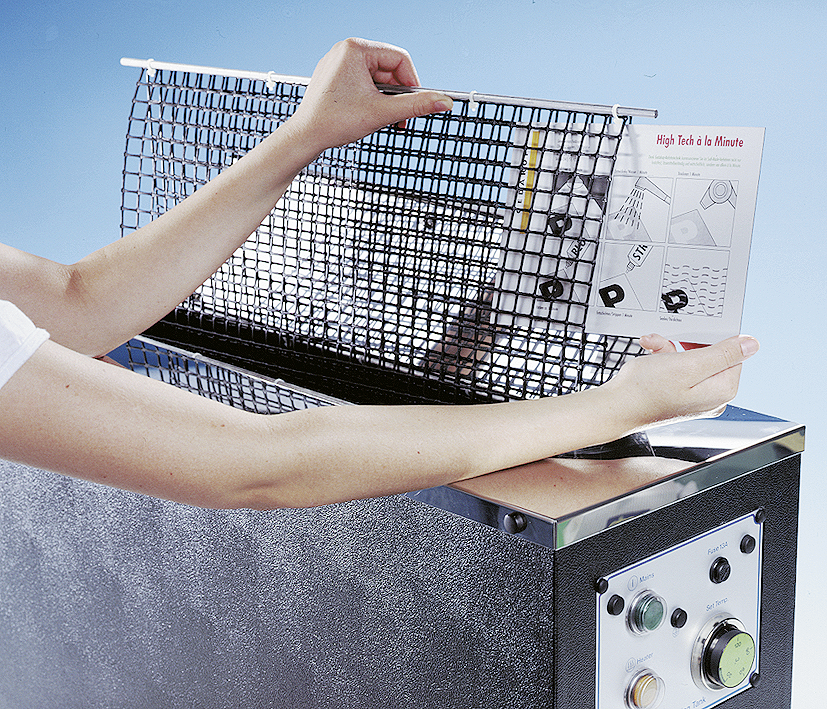

GEDAKOP system

anodized aluminum plates (CopyPhot plates)

Fastest possible, copy-processed production of inexpensive, multi-colored aluminum anodized signs.

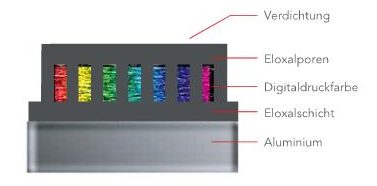

CopyPhot plates are anodized aluminum plates with open pores and a decorative surface structure, ideal for photomechanical printing purposes. CopyPhot sheets have a protective coating and a photo emulsion layer, ensuring a guaranteed shelf life of 8 months. The basic color silver is available in all thicknesses. Gold is only in 0.5; 1.0 and 2.0 mm available.

Individual pieces and small series. No specialist knowledge is required. Possible print templates include: offset or red film, polyester sheet printout, GEDA Laser Star from laser printers, blackened with GEDA Black. GEDAKOP COPY in minutes with the GEDAKOP system.

Deutsch

Deutsch Français

Français