Eloxal digital printing

The open-pore anodized aluminum is optimized with a special pore size for direct printing in digital printing. The material can also be printed with our water-based GEDACOLOR screen printing inks (N).

The open-pore anodized aluminum is optimized with a special pore size for direct printing in digital printing. The material can also be printed with our water-based GEDACOLOR screen printing inks (N).

GEDACOLOR digital printing plates, specially anodized plates for digital aluminum anodized negative printing.

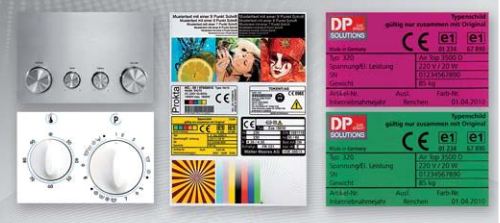

Inexpensive and quick creation of individual pieces in small format: Since summer 2009, in collaboration with our cooperation partner DP Solutions, we have been offering starter packages for digital anodized underprinting on aluminum to create multicolored, photorealistic industrial and advertising signs.

Anodising vacuum is a process for surface refinement of aluminum in which aluminum plates are directly printed with an initially open-pored protective layer obtained through anodic oxidation and then compacted in a hot water bath at over 97 °C. The temperature of the water in the so-called seal bath causes the volume of the printed material to increase and thus the closure of the open pores of the oxide layer. The colors trapped beneath the surface are extremely resistant to chemical, mechanical and thermal stress due to being sealed in a hot water bath. Even graffiti can be easily removed using appropriate cleaning products without damaging the print.

Request your individual sample today or arrange a personal demo appointment with us.

Eloxal digital printing is an advanced technology used in various applications. This technique allows aluminum surfaces to be printed with high-resolution images and designs, achieving unique aesthetics and durability.

The term “eloxal” comes from the short form of “electrolytic oxidation of aluminum”. It is a special treatment that creates a thin, transparent oxide layer on the surface of the aluminum. This layer not only offers improved corrosion resistance, but also allows the absorption of dyes that permanently color the aluminum.

With Eloxal digital printing, this process is combined with the use of digital printing technologies. It enables the individual design of aluminum surfaces with complex patterns, images, texts or scales. By using special inks and printing processes, almost unlimited color variations can be achieved, which can also result in works of art being created on aluminum surfaces.

Sub-anodized printing has become increasingly important in recent years and offers numerous advantages. With this innovative printing technology, aluminum is anodized and refined with digitally printed motifs. The most important advantages of Eloxal digital printing are explained below.

The anodized underprint enables a high level of detail and precise reproduction of colors and patterns. Digital printing technology allows even the finest details and complicated patterns to be printed on the anodized aluminum. This allows us to create high-quality, individual designs that fully meet customer requirements.

A big advantage of Eloxal negative printing is the longevity of the printed motifs. Since the ink is printed directly into the anodized aluminum, it is particularly resistant to external influences such as scratches or cleaning agents. The printed motifs retain their color intensity and originality over a long period of time.

Eloxal digital printing is also extremely versatile, such as in mechanical engineering, trade fair construction or advertising technology. The ability to print individual motifs allows us to offer our customers tailor-made solutions.

Another big advantage of sub-anodized printing is the efficiency and speed of production. By using the latest printing technology, large quantities of anodized aluminum can be printed in a short time, including with different content on the signs, e.g. consecutive serial numbers, barcodes, QR codes, data matrix codes, etc. This means we can guarantee high quality and punctuality even for orders with tight deadlines.

In addition to the advantages mentioned, Eloxal digital printing also offers ecological advantages. Using anodized aluminum as a printing material is environmentally friendly as it is 100% recyclable and does not release harmful substances. This means we ensure sustainability and environmental friendliness in your printing projects.

In summary, sub-anodized printing offers numerous advantages. From the high level of detail and longevity of the printed motifs to the versatility and efficiency of production, printing technology enables tailor-made, high-quality solutions. Due to the ecological advantages of recyclable anodized aluminum, anodized vacuum remains a first-class choice in terms of sustainability and environmental friendliness.

Technical features

Typical application

Technical data

| Per 1000 8+ | Per 1000 10+ | Per 1000 13+ | Per 1000 16+ | |

|

|

|

|

|

| technology | Piezo inkjet IR | Piezo inkjet IR | Piezo inkjet IR | Piezo inkjet IR |

| Max number Colors | 8th | 8th | 8th | 8th |

| Max resolution | 1440x1440dpi | 1440x1440dpi | 1440x1440dpi | 1440x1440dpi |

| Max print speed | <14m2/h depending on the print medium |

<14m2/h depending on the print medium |

<14m2/h depending on the print medium |

<14m2/h depending on the print medium |

| Max pressure range | 800×1300mm | 1090×2000mm | 1361×2000mm | 1610×3200mm |

| Max height adjustment | 200mm | 200mm | 200mm | 200mm |

| software | RIP | RIP | RIP | RIP |

| Dimensions | 2000x2450x1450mm | 2255x3100x1650mm | 2525x3100x1650mm | 2775x3900x1650mm |

| Weight | 495kg | 730kg | 980kg | 1530kg |